1st March 2022

Suffolk County Council Trading Standards are responsible for ensuring the goods arriving at the Port of Felixstowe are safe for the UK market. The Imports Team is 100% funded by the Office for Product Safety & Standards (OPSS). When they came across some suspect ladders in July 2021, their first point of call was the Test & Research Centre (T&R).

In the largest consignment of telescopic ladders detained to date, just over 2000 were detained and inspected by Trading Standards officers.

Three different length models were found; 2.6m, 3.2m and 3.8m.

The Test & Research Centre assessed the ladders against BS EN 131-6, the British and European standard for telescopic ladders. Samples of each size were supplied for assessment against limited clauses of BS EN 131-6, focusing on the key dimensions and strength requirements.

The findings were worrying. During several strength tests, the ladder samples buckled or broke before the full test load could be applied. This would suggest that these ladders could break whilst in normal use – causing a fall from height and risk of injury or fatality.

Based on our testing, Suffolk Trading Standards were able to prevent these dangerous ladders from entering the UK market. These ladders were published on the new UK product safety database in January.

Thanks to Trading Standards efforts and our testing, the unsafe ladders were destroyed before they could reach their destination – a listing on amazon.co.uk.

The 3.2m and 3.8m ladders did not conform to the dimensional requirements of EN 131-6. The width of the ladder where it rests on the ground, known as base width, was too small. For the 3.8m ladder, it was nearly half the width it should be. This could contribute to an increased risk of a fall from height, as the width of the base influences the stability of the ladder in use.

In addition, all the samples could have the rungs locked into any position. EN 131-6 requires that “by construction” spare rungs are stored at the top of the ladder. Rungs that can be positioned anywhere mean the distance between consecutive rungs can vary. This increases the risk of a fall from height, as the user may miss a rung when climbing or descending.

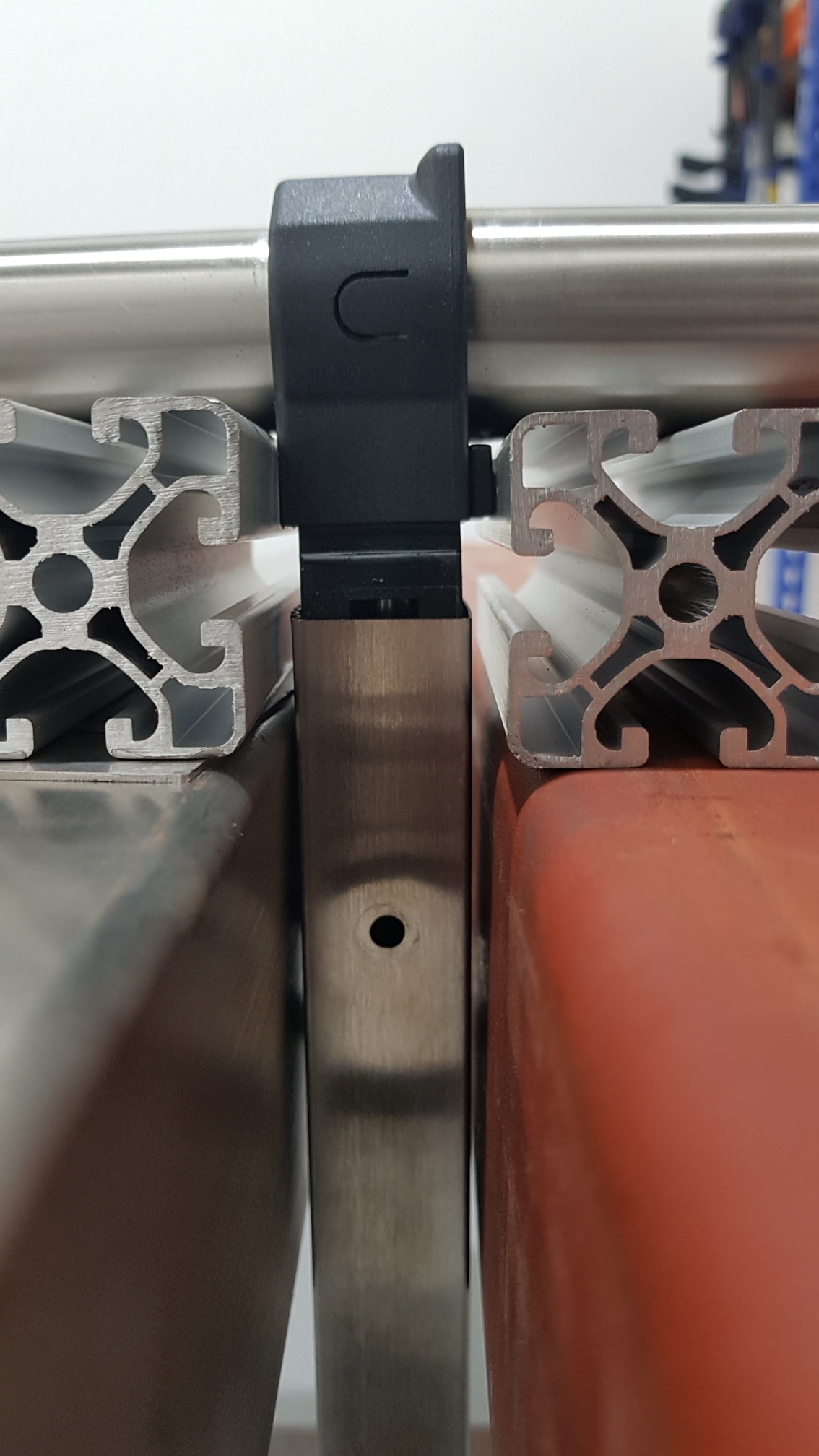

EN 131-6 also requires that telescopic ladders have a mechanism that protects the users’ hands from crushing when it’s being closed. This can be either a soft-closing mechanism or the use of spacers to prevent finger crushing.

None of the samples had anything to prevent injury – when the ladder was unlocked at the bottom, the full weight of the ladder fell downwards.

EN 131-6 has several different strength and deflection tests, which assess the capabilities of the product in different ways.

The samples performed poorly on the deflection testing.

The bending test applies 750N (76kg) across both stiles in the centre of the ladder, whilst each end is supported on rollers. Deflection is then measured in the middle. The deflection limit is based on a calculation of the length of the ladder. All three samples failed this test, with the 3.8m performing worst, exceeding the deflection limit by just over 60%.

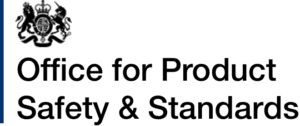

On telescopic ladders, the rungs are joined to the round stiles with plastic brackets. The strength of the connection is vital to ensure that the weight of the user is fully supported. To test this aspect of the design, the ladder is laid on its side and hung from the upper stile. Supports are placed on either side of a rung for testing. A test load of 2600N (265kg) is applied to the lower stile of the same rung. The ladder must support the test load without being damaged and be safe to use.

Neither of the three samples could support the test load. The plastic brackets either snapped or the connecting rivets sheared. In use, such a poor connection could contribute to a fall from height.

Finally, to test the strength of the ladder whilst in use, the ladder is set to 65 degrees and a load of 2250N (229kg) is applied to the rung nearest the middle of the ladder.

On all three samples, the stile on the loaded side buckled. And this was before the full test load could be applied. This is perhaps the worst finding of all, as this would suggest that the ladder could fail in normal use, causing a fall from height.

The Test & Research Centre was founded to help make products and their users safer. Our continuing work with Trading Standards is helping to stop dangerous sub-standard products enter the supply chain. So far, we have helped Trading Standards stop over 2,800 ladders.

“Suffolk Trading Standards remains committed to protecting consumers from dangerous goods, often intercepting unsafe items before these even go on sale. As such, their Imports team carries out market surveillance at the Port of Felixstowe, working as part of the Office for Product Safety & Standards (OPSS) Product Safety at Ports & Borders Programme.

“ The dangerous goods stopped at the border by the Imports team includes thousands of substandard ladders, which were refused entry into the UK or destroyed following inspection and testing during partnership working with colleagues at the Test and Research Centre. These posed a significant risk to the public and could have caused serious injury, or even death, had they found their way into the marketplace.

“Of course, consumers can also protect themselves by only making purchases from reputable retailers and remaining vigilant. The CE mark is usually a good indication that an item has been manufactured to meet required safety requirements and should be found on goods such as toys, electrical items, and machinery. However, this doesn’t apply to ladders, so if they do bear the CE mark, this is a clear warning sign that they may be substandard. It’s also worth remembering that if a price looks too good to be true, you’re probably being offered an inferior product that hasn’t been adequately tested and could prove very harmful.”

Gail Hounslea, Chair of the Ladder Association, added:

“The condition of these ladders was truly shocking. Consumers have every right to expect the ladder they’re buying to be safe, but this case reminds us that there are dangerous products making their way into unsuspecting UK homes and workplaces.”

“If you’re purchasing a ladder, please be vigilant. Source ladders from reputable suppliers who put your safety first – any Ladder Association member is the recommended place to start.”

The Test & Research Centre was founded to help make access products and their users safer. We are committed to working with all stakeholders, including the Office for Product Safety and Standards and industry bodies like the Ladder Association, to ensure that users have access to products that conform with British and European Standards.

We work with Trading Standards Officers to offer advice and support on consumer access equipment safety.

We can provide targeted market surveillance testing for Trading Standards against:

34 Regal Drive, Soham, Cambridgeshire, CB7 5BE.

A UK-based Certification Body, Test Laboratory and training facility that specialises in access equipment.