24th February 2021

Suffolk County Council Trading Standards has an Imports Team focused on the Port of Felixstowe. As the UK’s largest container port, it handles over 4 million containers every year. From sporting goods to toys and ladders, everything coming into the port is under the watchful eye of Trading Standards Officers (TSO), supported by the Office for Product Safety & Standards (OPSS).

In February 2021, a spot check by TSO’s based at the port found a batch of ladders which raised suspicions.

The ladders were a model of telescopic standing ladders – ones that can be used in standing mode (like a step ladder) or leaning ladder mode (like an extension ladder). Its labels stated “EN 131” and carried some of the correct safety label symbols.

However, upon further inspection, these ladders had no product codes or date of manufacture. Also, there were no contact details of the supplier, either manufacturer or UK based distributor. All these details are required under the General Product Safety Regulations 2005 to help identify products placed on the UK market. This is vital should a product need to be recalled, or a consumer needs to contact the distributor if a problem with the product arises. The labels also showed a “CE” mark. Not only is there no EU directive under which access products (including ladders) can be CE marked, it is also illegal to wrongly mark a product as such.

Acting on these red flags, the TSO contacted Test & Research Centre, the UK’s specialist test laboratory for access products. Within a few days, the ladder was in the test lab undergoing an assessment against the British and European ladder standard, BS EN 131-4:2020 – Single and multiple hinge-joint ladders.

There are many tests a ladder must pass before it can be certified as EN 131 compliant. These include strength tests, slip tests, and cyclic tests of the joints and connections. The tests analyse different aspects of the design, with either a pass/fail based on strength or a limit based on the deflection. There are also specific requirements for materials and dimensions.

When a ladder passes all the relevant tests and requirements, it can be marked with the applicable parts of EN 131. This gives consumers confidence that the ladder meets basic safety standards.

Remember, this shipment of ladders was labeled ‘EN 131’. Had it undergone – and passed – all these tests and checks? We were about to find out.

Test & Research Centre agreed to evaluate the product against limited clauses of EN 131-4. To complete every single check is unnecessary for market surveillance purposes and would be prohibitively expensive for Trading Standards. Test & Research Centre agreed an evaluation package focused on safety-critical areas, such as:

It wasn’t long before serious non-conformities were found.

Firstly, the product was assessed against the dimensional requirements of:

Our assessment found that the base width was too small in both standing and leaning ladder modes. In leaning ladder mode it was 300mm too small and in standing ladder mode more than 250mm too small. The width at the base, where the ladder contacts the ground, provides the ladder and the user with a stable base to work from.

The ladder also had an inconsistent rung pitch. EN 131 requires ladders to have rungs consistently spaced within 2mm. On this ladder, the biggest difference was nearly 25mm. When you climb a ladder, you get used to stepping up at a regular pace – rungs being nearly an inch different could cause you to miss your footing and increase the risk of a fall from height.

Whilst moving the ladder around, another non-conformity was noted. EN 131 requires that rungs, steps, and treads have a slip-resistant surface. This is usually in the form of ribs or grooves on the standing surface. This ladder had those, but only one side of the rungs. In standing ladder mode, both sides were OK, but in leaning ladder mode, one-half of the ladder had the rungs upside down!

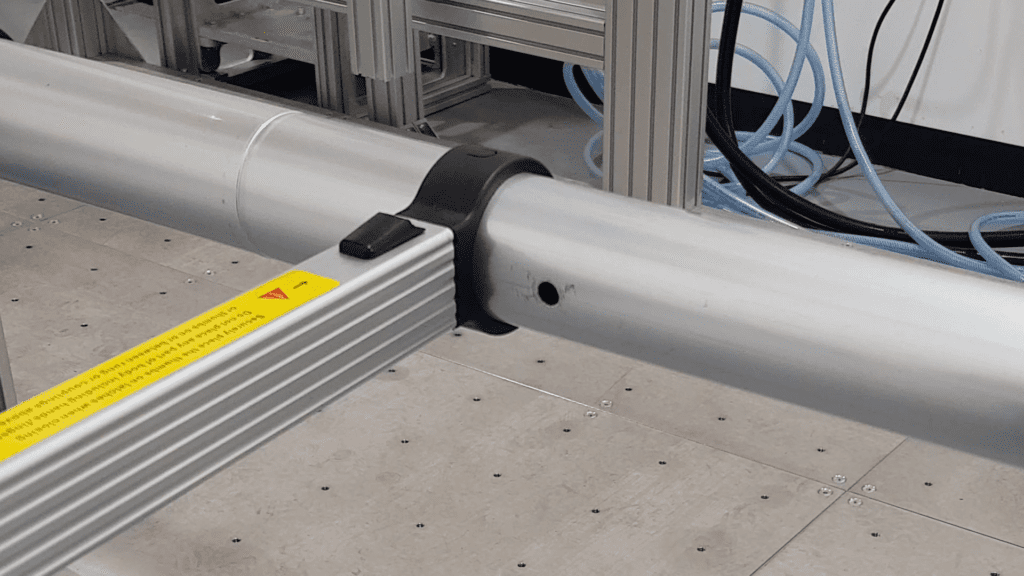

Whilst the dimensions were being checked, the most worrying discovery was made – the rungs could be separated from the plastic stile connections by hand!

EN 131-2 states that “Rungs and steps shall be firmly and durably connected to the stiles”.

Under light hand force, the stiles could be pulled apart, meaning the rungs could slide completely off the plastic connection joint. During use, with ladders being handled and moved around, it is likely that a rung joint could open up whilst you were standing on it.

We had already established that the connection between rung and stile was far from firm or durable. So it will come as no surprise that the ladder failed the first 4 out of 5 load tests according to EN 131-2 – Requirements, testing, marking.

Sometimes when we test a product, there’s a very narrow margin between a pass and a fail. Here the accuracy of measurement is crucial.

This was not the case with this ladder.

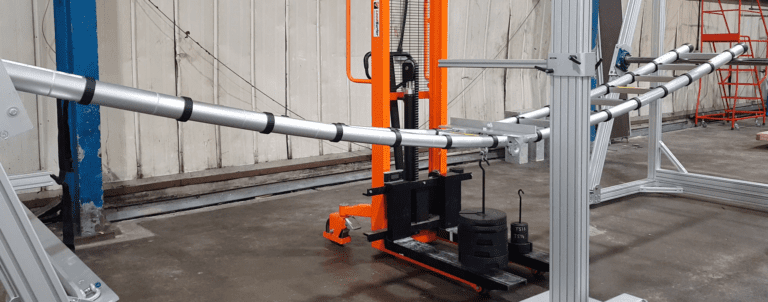

For example, the ladder was tested to the lateral deflection and bending tests in EN 131-2.

In these tests, the ladder is placed on support rollers 200mm from each end of the ladder. The test loads are then suspended from the centre point of the ladder. Deflection measurements are taken from where the loads are applied and deflection limits are calculated based on the length of the ladder.

For the lateral deflection test, the deflection limit was 23mm – the ladder actually deflected 100.5mm, over 4x greater than the limit.

On the bending test of the stiles, the deflection limit was 105mm – the ladder actually deflected 290mm, nearly 3x the deflection limit.

The straw that broke the camel’s back was the strength test.

In this test, the ladder is set up in its position of use, leaning against a wall. We started in leaning ladder mode, and if it passed this, would have moved onto standing ladder mode.

EN 131-2 has two ratings – Professional and Non-professional.

On some tests, the loads applied are different based on the rating. For this, we chose the lighter, Non-professional load, as there was nothing stated on the labels (another failure to EN 131-3), and it might have given it a fighting chance of passing. The product needs to withstand the test load for 1 minute and be usable again after the load is removed.

But before it got there, it suffered a structural failure in one stile. This was after the top section had been pulled almost flat to the vertical test wall, due to the lack of rigidity in the product.

More tests were planned, but due to the structural failure, testing was ceased after the strength test

Finally, the product was assessed against the requirements of EN 131-3 – Marking and user instructions. There were more failures here as well.

The markings (labels) on the product were missing quite a few of the mandatory safety pictograms – like “read the instructions” – as well as basic safety information like the positions the ladder can be used in and where the last usable rung is.

All in all, this ladder was not even close to passing the EN 131 requirements claimed by its labelling.

Due to the diligence of Trading Standards Officers at the Port of Felixstowe, 100 dangerous ladders were seized for further investigation. With the Test & Research Centre’s help, testing proved that Trading Standards’ suspicions were correct and they were right to prevent them from entering the UK.

“Our Imports Surveillance Team at the Port of Felixstowe is funded by the Office for Product Safety and Standards, and its role is to protect consumers from unsafe and dangerous goods, just like these ladders.

“We stop these products reaching our shops or online marketplaces so that members of the public don’t even get the chance to buy them. We will physically check consignments at the port, and detain anything which is unsafe or dangerous. The whole process is a great team effort, from the intelligence we receive about consignments arriving at the port, through to having the items tested.

“When you’re shopping online, it is tempting to pick up those amazing deals that you see on social media or in online marketplaces. But if a price looks too good to be true, there’s usually a reason why. We encourage people to only make purchases from reputable retailers and to check the product for conformity to standards – if these marks are missing, the product hasn’t been tested to ensure it complies with the necessary safety requirements and could be a serious risk.”

“These are quite possibly the most dangerous ladders I have ever come across. The poor connections between the rung and stile are the most troubling. I have no doubt that in use these could have failed.

Sadly, it’s not a case that only in a ‘certain scenario’ these could have failed – the connection is so poor it’s highly likely to fail during normal use. There were 100 dangerous ladders in that shipment and each of these was a fall from height waiting to happen.”

Gail Hounslea, Chair of the Ladder Association, added:

“The condition of these ladders was truly shocking. Consumers have every right to expect the ladder they’re buying to be safe, but this case reminds us that unscrupulous suppliers are still trying to sneak dangerous products into unsuspecting UK homes and workplaces. If you’re purchasing a ladder, please be vigilant. Source ladders from reputable suppliers who put your safety first – any Ladder Association member is a fantastic place to start – and ask to see proof of certification to BS EN 131.”

The Test & Research Centre was founded to help make access products and their users safer. We are committed to working with all stakeholders, including the Office for Product Safety and Standards and industry bodies like the Ladder Association, to ensure that users have access to products that conform with British and European Standards.

We work with Trading Standards Officers to offer advice and support on consumer access equipment safety.

We can provide targeted market surveillance testing for Trading Standards against:

34 Regal Drive, Soham, Cambridgeshire, CB7 5BE.

A UK-based Certification Body, Test Laboratory and training facility that specialises in access equipment.